Ascent to Absolute Engineering

Operating at the Finishing Line

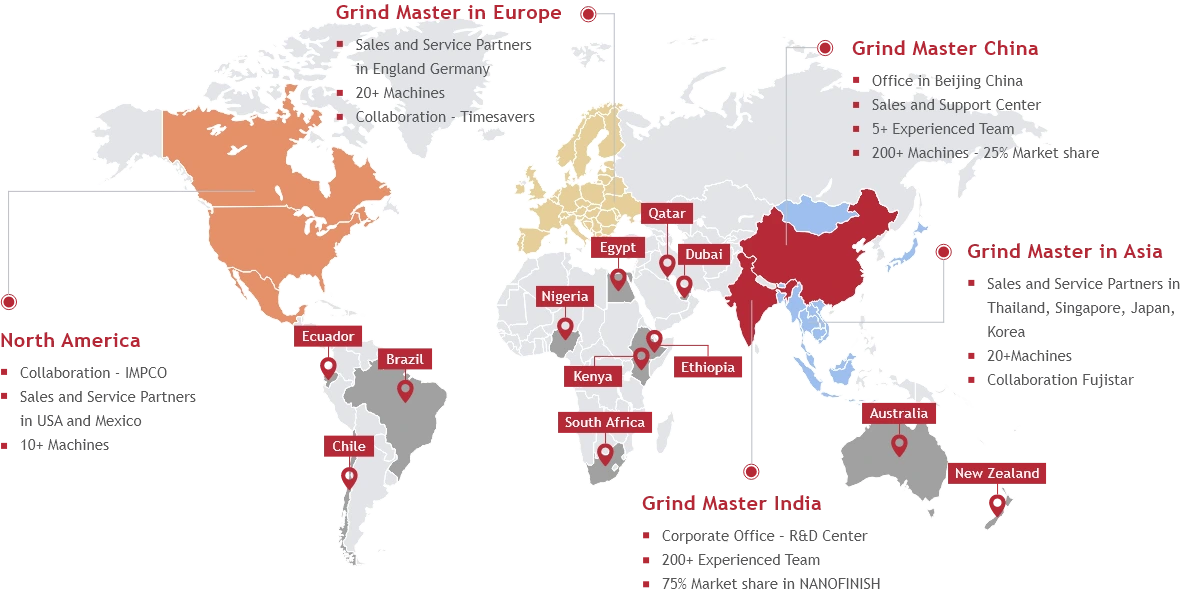

Forging Partnerships Worldwide

Empowering Through Values

Read Our Story – Garage To Global

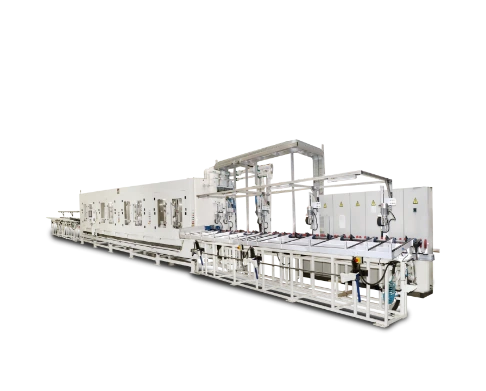

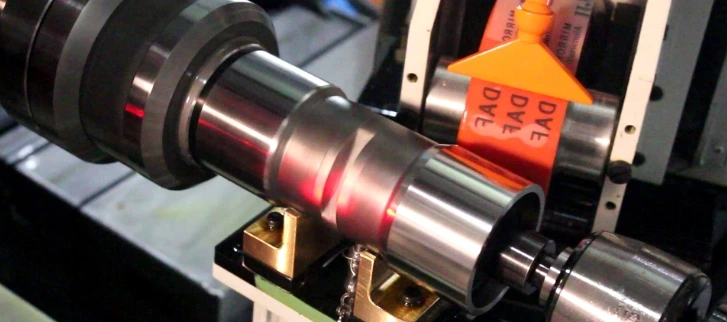

Our Products

We are Different

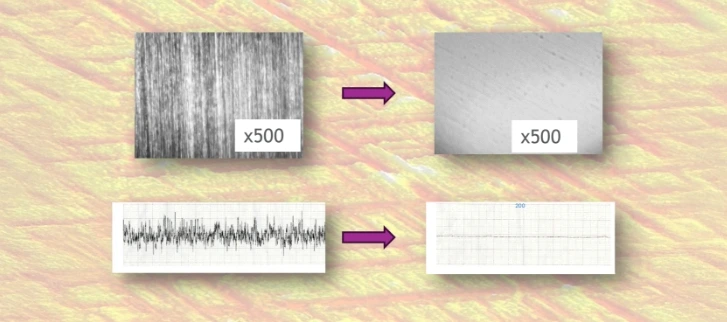

Our Expertise in Specialized Machine Solutions for Finishing

Our Advanced Research and Development Facility

Our Strong Global Presence and Collaborations

What it means to be Grind Master

1984

The foundation year of Grind Master5,500

Number of machines delivered worldwide30

Number of innovations patented10,000

Sq. m. of integrated manufacturing facilityTrusted By Leaders

- Tata Motors

- Bharat Forge

- Maruti Suzuki

- SAIC

- PSA

- Linamar

- Mahindra

- Precision Camshafts

- Renault Nissan

- Great Wall Motors

- Bosch

- John Deere

- Bajaj

- Happy Forging

- Honda

- Changan

- Gewis

- Delphi

- TVS

- Kalyani Techno Forge

- Showa

- Geely

- MVO

- Tecumseh

- Ashok Leyland

- Netalkar Group

- Nissan

- AAM

- Renault

- Ford

- Royal Enfield

- SAC

- Toyota

- BYD Auto

- Benninger

- Cummins

Customer Testimonials

We greatly appreciate your collaboration with our organization and the invaluable services you provided, especially in establishing facilities for our new plant at Pantnagar.

We commend you on your excellent yearly vendor quality rating. Your dedication to maintaining high-quality supplies is truly appreciated, and we look forward to your continued excellence.

I’m pleased to inform you that the grinding machine has arrived and has been successfully installed. Everything is working as expected, and we are extremely satisfied with it.

We are truly satisfied with the machine, as it met all our expectations. Thank you for providing such excellent equipment.

Your facility is truly state-of-the-art, and I appreciate the high standards you’ve set. The team is an absolute pleasure to work with, making every collaboration seamless.

We have over 12 machines now. The machines produce good quality parts. For every new project with Grind Master, they have ensured there is an improvement over the previous version of the machine. Grind Master has responded to every requirement of General Motors. The hands-on approach by Grind Master’s owner also shows their commitment. We can cooperate for many more years to develop technology and good relations.

Grind Master made our life easy — first with microfinishers and later with balancers. Our relationship with Grind Master has been very friendly. I have given both positive and negative feedback, and they have been listened to. Being a nationalist, I do not like to send money abroad. Grind Master was one of the first quality Indian-made machines in the crankshaft line.

Over the years, the collaborative working between SGM and Grind Master resulted in good-value engineering and optimised concepts for the machines. Grind Master offered good service and support that gave us a lot of confidence to continue working on this business relationship.

The machine quality meets international standards, and Grind Master offers outstanding service support and spare parts.

Latest Updates

- IMTEX Forming 2024 Exhibition held at Bangalore Karnataka (India),31 January, 2024

- Grind Master received Overwhelming response at JIMTOF 2024 in Japan18 November, 2024

- IMTEX 2025 invitation1 January, 2025

- Grind Master wins IMTMA Best Design Award at IMTEX 202525 January, 2025

- Grind Master at IMTEX 2026!21ˢᵗ – 25ᵗʰ January 2026

Service & Support

Quick Links

Grind Master

Follow us

Accreditations